CHALLENGE

To propose an optimal analog front-end architecture and consecutively develop the electronic circuits for a given capacitive MEMS pressure sensor. The front end should accurately measure the pressure in a tire and be robust against leakage, parasitics and noise.

SOLUTION

The SystematIC design methodology was effectively applied in this project. The physical pressure parameters are converted to the electronic domain by MEMS pressure sensors. In the first phase of the project, the MEMS sensor was electronically modeled to determine an optimal excitation and read out architecture regarding noise, offset and accuracy of the transfer function. Various options of linear and switching configurations were evaluated and an architecture was selected. In the detailed IC design the frontend was designed and layouted for a modern automotive IC application, taking process varioation and wide temperature range into account. The design includes safety and extensive test features.

TIME

In 4 weeks time we produced an architecture proposal. Following this, the detailed design and layout of the front end was completed in close cooperation with the customer.

WE ARE PROUD

An excellent design was made by SystematIC in a 180nm CMOS IC process that allowed the customer to apply for patent. Excellence of this award-winning product is well recognized in the market.

BENEFITS FOR CUSTOMER

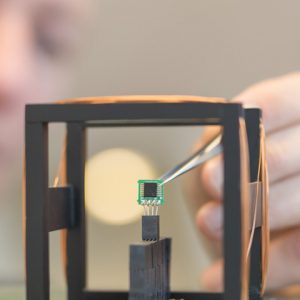

The analog front end provided the customer with a state of the art design and a key functional block for the smallest TPMS product in the market.

KEY TECHNICAL STATISTICS

- Temperature range: -40 ⁰C to 125 ⁰C

- Supply Voltage range: 1.8 V to 3.6 V

- Non-linearity: < ± 5% F.S.

- Sensitivity: 0.125 fF/G

- 450G range with 12-bit resolution

OUR OTHER SUCCESS STORIES

Successful achievement of your company’s goals will require IC solutions that are tailor made for your business needs. SystematIC was founded to help businesses imagine, plan, and develop these IC solutions.